Lumpi undertakes the design and development of fully automated manufacturing systems. These systems can incorporate a variety of pre-existing laser sources or we can include the development of bespoke sources in the design package (like excimer lasers, specialised wavelength sources (mid-IR, far-IR, vasuum UV etc). The systems can also incorporate automated product clamping and positioning, robot systems or conveyor belts, milling drivers, plasma or oxy-fuel sources, powder blasting, inductive heaters etc. They can further include process monitoring and closed feedback controls, product inspection metrology like dimensions, imaging, weld NDT and more. Support systems like fume extraction and filtering, off-cuts, dross, fluids and powder collection and recycling. The systems can be integrated with the rest of the manufacturing line or as stand alone systems in the shop floor or inside laser process cells to meet the client’s needs.

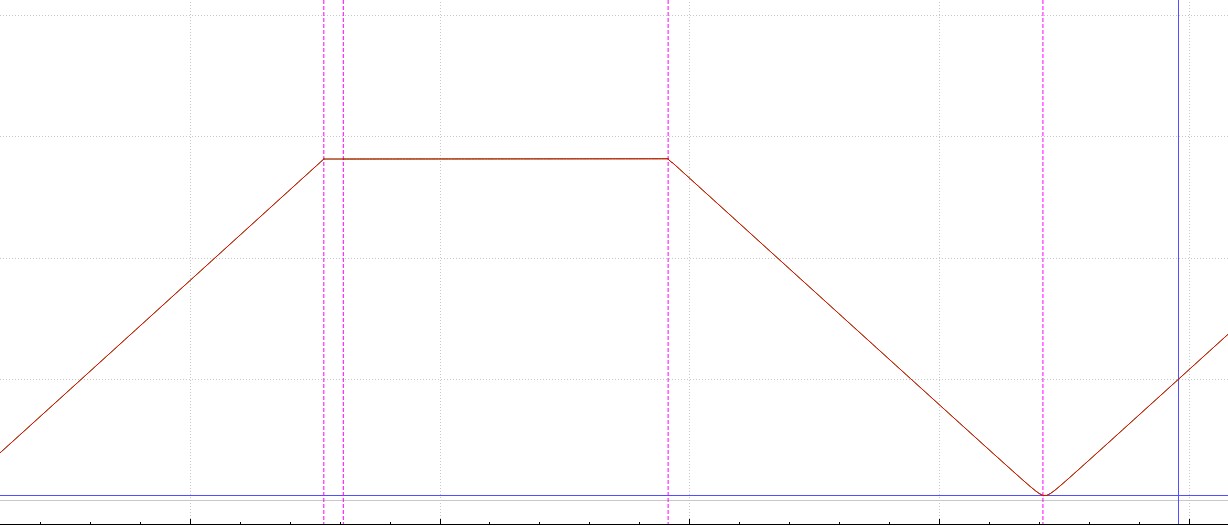

Lumpi conducts optical design for laser optical trains of lenses in the beam delivery system. Systems including beam resizing and reshaping optics, elliptical or line focus, masked beam imaging and other beam configurations can be achieved. Our designs aim at minimising aberrations and achieving optimised contrast and small spots. Optical design can be combined with mechanical design of the surrounding mounts and enclosures to create bespoke engineering solutions for beam delivery and beam management. More complex designs can include beam motion systems or sample management mechanics and motors for a fully automated process station. The designs can match existing laser systems and robotic mounts or interface with other manufacturing line equipment and conveyors.

Optical and opto-mechanical design can also be undertaken for imaging lenses, optical sensing systems and imaging systems.

Optical design can be conducted using our own optical CAD tools or mainstream design packages like Zeemax and our proprietary off-line mechanical CAD software.

Design services can be provided on a pro-rata basis or as a structured quotation against a fixed engineering specification. Call us or email us for an introductory meeting, where we can review your design requirements and recommend the best way forward.